1.Fingqa ukufakwa

Indawo yokufakwa kwefeni

Izaziso zokukhetha isikhundla zimi kanje:

Uma ifeni emoyeni evulekile, kufanele ibe nesivikelo.

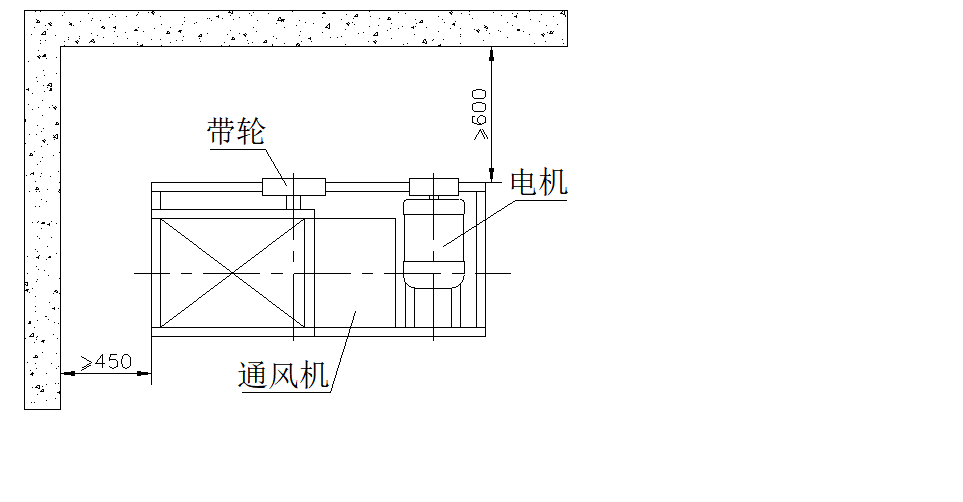

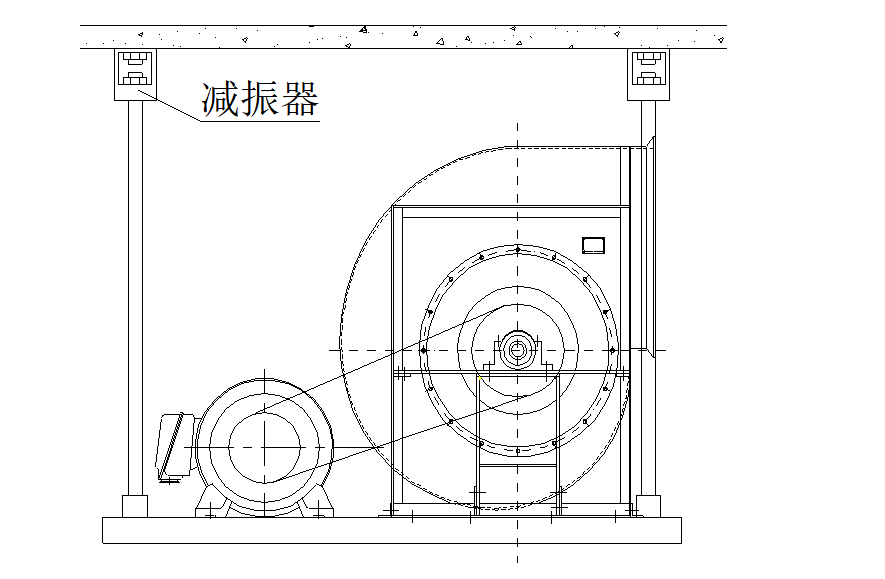

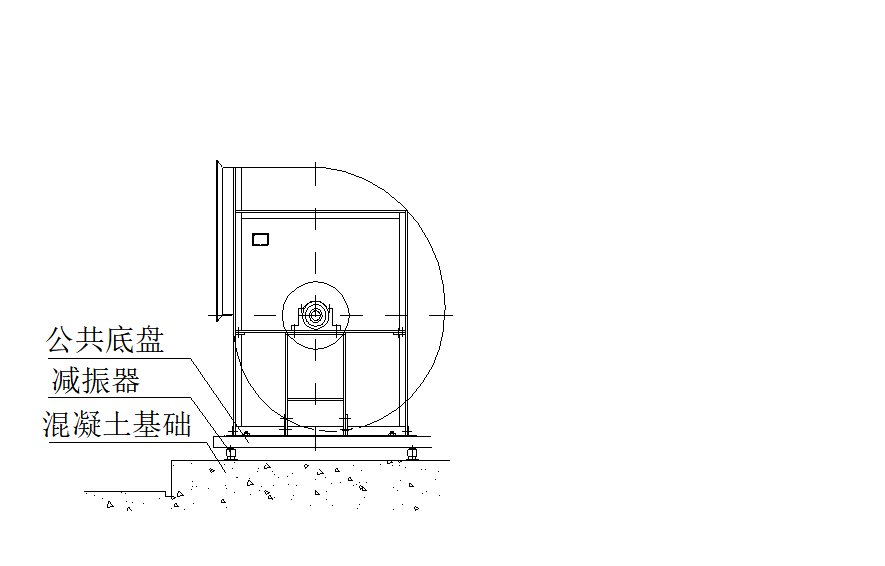

Ifeni kufanele ifakwe endaweni lapho kulula ukuyiphatha nokuyibuka. Bona umdwebo 1.

Umdwebo 1

Indawo kufanele ibe nesisekelo esiqinile.

Ikakhulukazi ifeni izofakwa kuhlaka olungaphezulu, indawo ayinayo into yokudlidliza okufanele.

2.Izidingo zendawo

Kufanele unake ukulinganisa i-acreage yokufaka ngale ndlela elandelayo:

Ungaphazamisi omunye umshini eduze kwayo.

Hlola futhi ulungise kalula.

Kunesikhala esanele sokususa i-impeller.

3.Izindlela nezimfuno zokufakwa

1.Beka phansi.

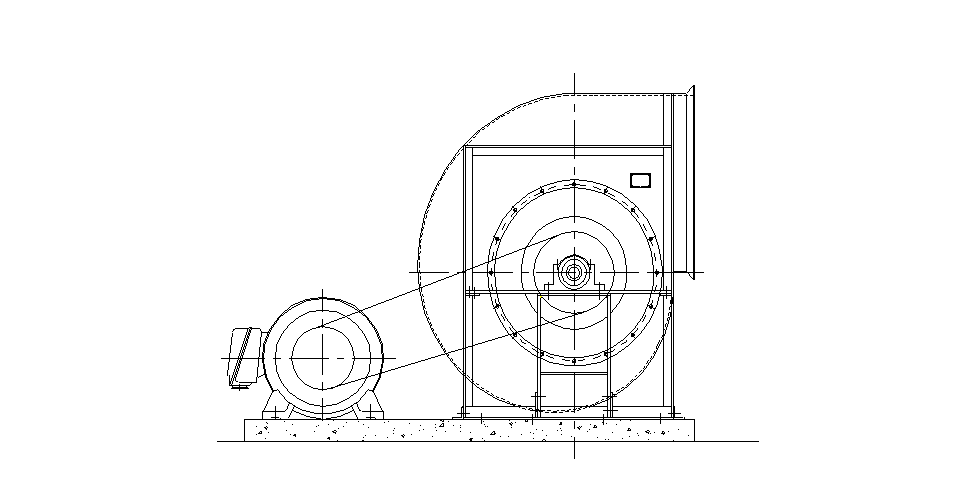

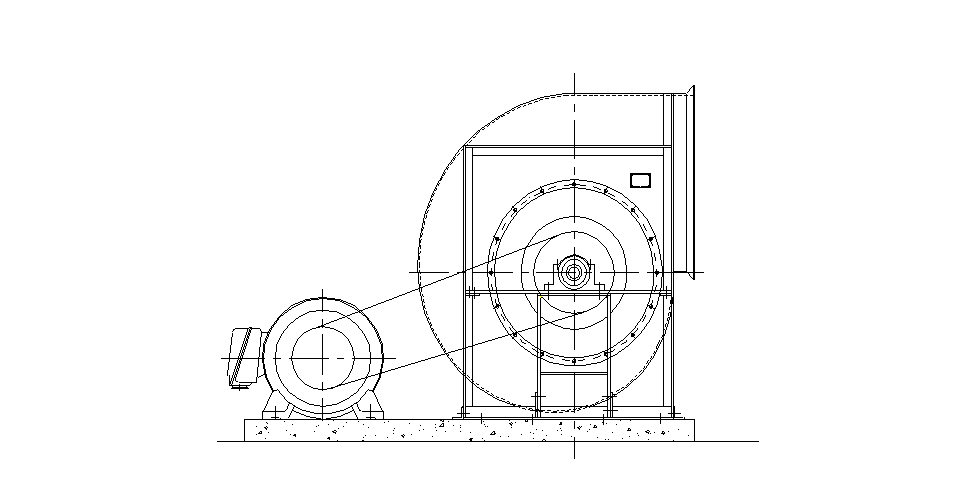

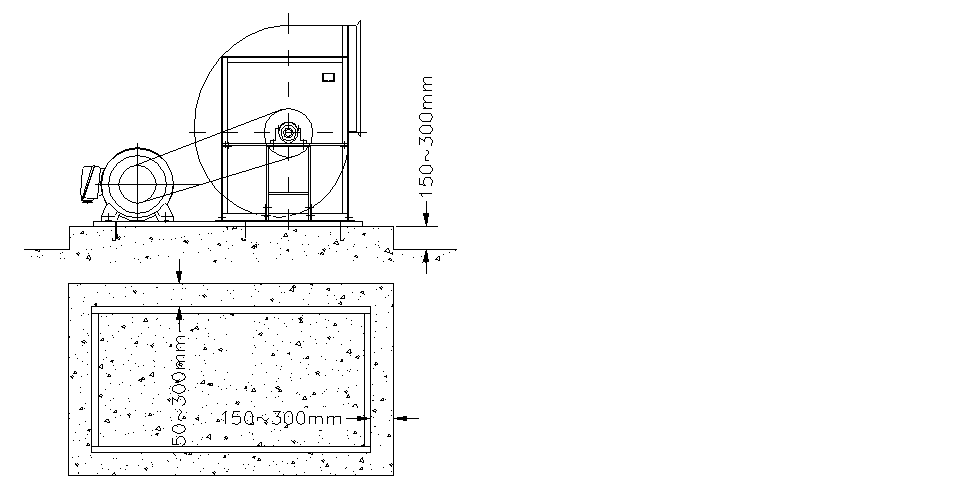

Amafeni ajwayele ukufakwa phezu kombhede okhonkolo ngaphandle kokuthi abalandeli bancane ngohlobo oluncane namandla emoto. Noma kunjalo, kufanele unake ukuqina kokuyisisekelo. Bheka umdwebo 2.

Umdwebo 2

2.Be efakwe ku-hathpace.

Kufanele unake ukuqina kwe-angular nokuqina kwendawo yokufaka ukuze ugweme i-resonance, ngaphandle kwalokho thatha isilinganiso sokuqinisa. Bheka umdwebo 3A.

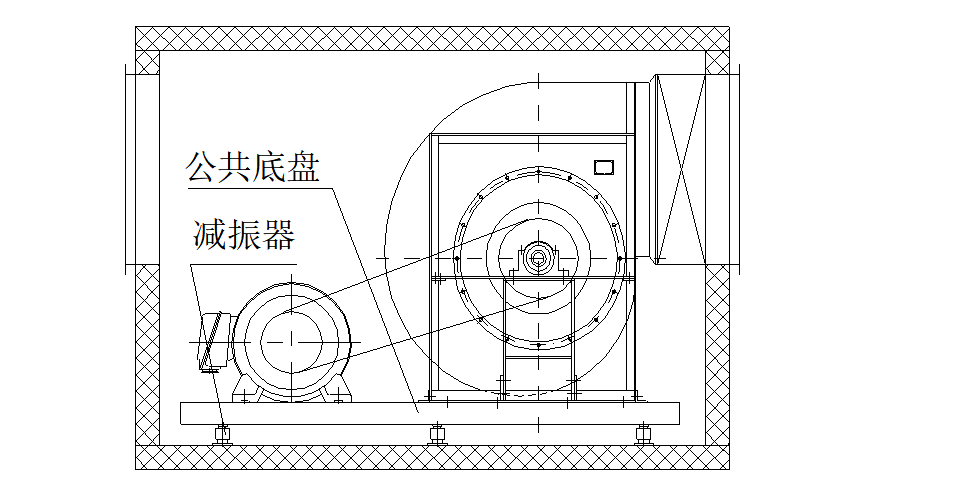

3.Beka ebhokisini labalandeli.

Ukuze ugweme ukukhululwa okungabangelwa ukuntuleka kokuqina nokuqina kohlaka, kufanele unake ukuqina. Ikakhulukazi uma usebenzisa irabha noma isidambisi-manzi sokudlidliza kwentwasahlobo, ifeni kanye nenjini kuzofakwa kupani yangaphansi efanayo. Bheka umdwebo 3B.

Umdwebo 3A

Umdwebo 3B

Umdwebo 4A

Umdwebo 4B

4.Kulengiswa ophahleni

Amafeni amancane kufanele afakwe ngamabhawodi kalula, (Bheka umdwebo 4A). Amafeni anosayizi omaphakathi kufanele afakwe ngokushiselwa kohlaka, kodwa afakwe phansi ngokusemandleni akho.

Lapho abalandeli be-exhaust kufanele bafakwe odongeni, udonga kufanele luqine.

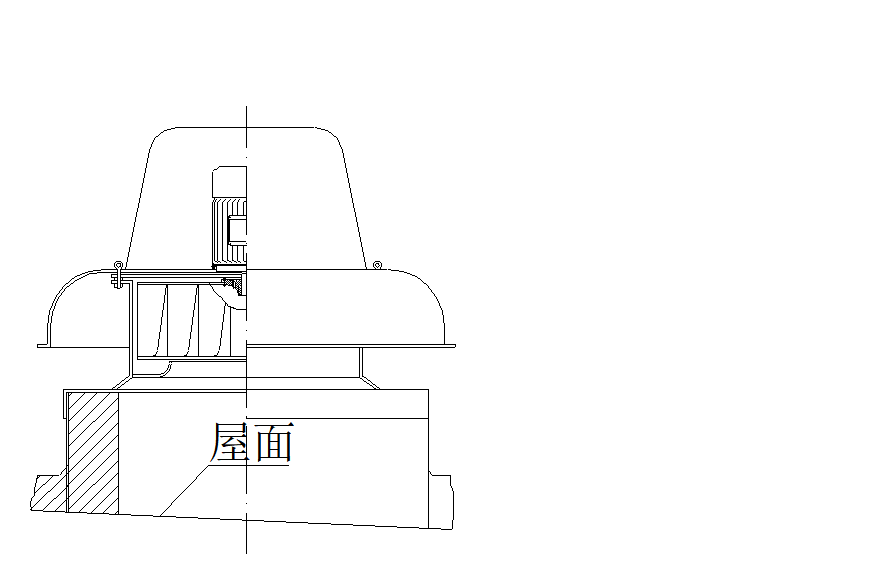

Kufakwe ophahleni.

Kufanele ucabange ngemiphumela yesiphepho, imvula neqhwa. Bheka umdwebo 4B.

2.Okuyisisekelo

1.Itshe eliwukhonkolo

Usayizi wendiza yedwala likakhonkolo likhulu ngo-150~300mm kunosayizi womngcele wabalandeli. Osayizi bedwala likakhonkolo labalandeli abancane bathatha ubuncane kodwa ukujiya kwalo kungaphezu kuka-150mm okufanele futhi isisindo sikhulu ngokuphindaphinda okungu-5 ~ 10 kunesisindo sefeni eliphelele. Bheka umdwebo 5

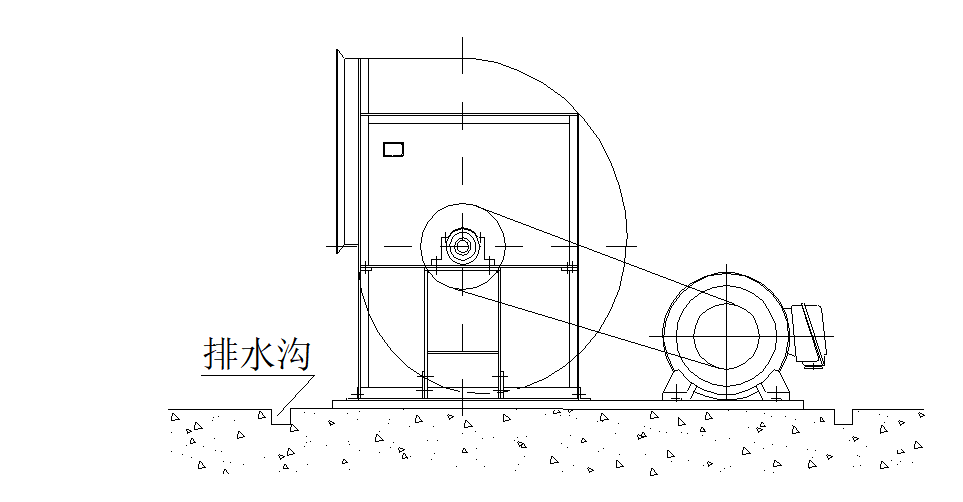

Kufanele ukhweze i-drain ukuze kungabikho manzi endaweni eyisisekelo, nokuthi ngeke iguguleke. Bheka umdwebo 6.

Ubuso besisekelo bushelelezi futhi buyancipha, kufanele ucabange ngezimbobo zokufaka ama-bolts kusengaphambili.

Umdwebo 5

Umdwebo 6

Lawula indawo eyisisekelo kanye nefreyimu yefeni nge-gasket, bese ulungisa ngemva kokuthintana ne-gasket ngokwanele.

2.Isici esingenakunyakaziswa

Izinto ezingenakunyakaziswa zihlanganisa ama-gaskets, irabha, intwasahlobo nokunye. Bheka umdwebo 7.

Kungcono ukhethe izakhi ezilungile ezingenakunyakaziswa ngokuya ngesisindo nemvamisa yokusebenza kwefeni. Uma ifeni isebenza ngesivinini esiphansi noma ilayisha kancane, into enganyakazi ingakhetha irabha.

Umdwebo 7

3.Ukusetshenziswa kwesici esinganyakazisi

I-underpan lapho ifake khona ifeni kanye nenjini inokuqina okwanele kwe-angular uma usebenzisa isici esinganyakazi.

Okuyisisekelo umtholampilo ngenxa yazo zonke izici ezingenakunyakaziswa zilingana. Uma kukhona okuthile ngaphansi kohlaka, ifeni inganyakaziswa ngendlela engavamile.

Uma usebenzisa i-elementi enganyakazi, kufanele ufake i-tie-in eguquguqukayo ekuhlanganyeleni kwepayipi lefeni.

Ibhalansi ye-impeller izobhujiswa lapho uthuli noma i-eyewinker ibambelela ku-impeller, kulokhu, sebenzisa isici se-shakeproof akulungile.

3.Izokuthutha, idiphozithi, igcinwe ngokuphepha

Bonke abalandeli bahlole ngokulungiswa kwesikhungo, ibhalansi, ukugijima, wabe esefaneleka ukuphuma embonini, ngakho-ke iklayenti kufanele linake i-abrade kanye nokuhlanekezela ngesikhathi sokuthutha.

1.Hlola izingxenye

Hlola abalandeli ukuthi banawo yini ukulahlwa, ukuhlanekezela, upende ophelele.

Hlola izingxenye nezingxenye ezisele.

2.Phakamisa futhi uhambe

Sicela usebenzise ihhuku lapho uhamba, u-perching futhi uphakamisa.

Uma uphakamisa i-fission casing kanye nama-rotor, gcwalisa ngokuthambile lapho ukurijwa kanye nocezu lokusebenza luthinte khona, ikakhulukazi i-impeller ne-shaft. Uma kungenjalo kuzokwehlisa ukunemba kokulinganisa, kuphumele ekutheni ifeni inyakaziswe.

Naka ukulungisa ama-rigging we-pulley kanye nezingono zokugcoba ngethusi zisengozini.

Ukuhamba kwemishini kuletha amandla amakhulu e-shaft, i-pulley ne-impeller, sicela uyikhangise.

Ukuhamba kwemishini kuletha amandla amakhulu e-shaft, i-pulley ne-impeller, sicela uyikhangise.

Ngesikhathi sokugcina, gcizelela ukuthi ujije kabili ngenyanga okungenani, ujike u-10 njalo futhi ume endaweni engaphezu kuka-180 °. Ngesikhathi esifanayo, qaphela izinga lokuzalanisa i-lubrication. Okwesibili, ezinye izikhathi zokuvula nokuvala i-rotor njengomnyango oguquguqukayo, uma kunesidingo, faka i-lube ukuze uvimbele ukugqwala.

Ukuhlola i-libricate ngemva kokuvula ikhava yokufaka uma ifeni ingazange isebenze isikhathi eside, engeza ilube entsha uma kudingeka.

4.Izindlela zokufaka

Yize ifeni kanye nenjini ihloliwe ngaphambi kokuphuma kwefekthri, kufanele uphinde uhlole ngemuva kokuthi ifeni izofakwa esisekelweni ngenxa yezokuthutha kanye nokuhlanekezeka okuguquguqukayo kwesisekelo ngeseshini ngayinye.

1.Ukulungiswa

Empeleni, indiza yabalandeli ithatha ibhentshimakhi ene-shaft, kodwa uma isiphephetha-moya se-axile sizofakwa ngohlobo olumile, indiza nayo ithatha ibhentshimakhi enekhava ye-V-belt noma ihabhu le-impeller.

Hlola indiza nge-gradienter ngemva kokupaka ifeni kusisekelo sikakhonkolo esibushelelezi, linganisa indiza ngama-gaskets phakathi kwefeni nesisekelo, bese ugcwalisa i-grout. Ngesikhathi esifanayo, gcwalisa i-grout emigodini yamabhawodi elungiselelwe ngaphambili, futhi ulungise amabhawodi ngokuqondile.

Qinisa amabhawodi e-basal ngokulinganayo, noma-ke uzohola uhambo lwesikhungo se-shaft kanye ne-scathe yamabhere.

Kulokhu, kungcono ucabange ngama-bearings okushintshanisa ngokushesha futhi ungayeki phansi ifeni uzame okusemandleni akho.

Setha iwindi noma umnyango wokuhlola nokushintshanisa ama-bearings.

Uma isiphephetha-moya sifakwe nge-spring damper, izimfuneko zokuphakama ezilinganiselwe ku-Shedi 1 zizofinyelelwa: iyunithi: mm

| Ubude be-Chassis L | ≤2000 | >2000~3000 | >3000~4000 | >4000 | Amanothi |

| Ukubekezelelana | 3~5 | 4~6 | 5~7 | 6~8 | Ukubekezelelana Okulinganiselayo |

| Qaphela: Ubude be-damper elayishiwe buzoba yinto efanayo, futhi ilayishwe kuphela ngamandla aqondile, ngaphandle kwanoma yimaphi amandla ama-tangential noma ama-torsion. | |||||

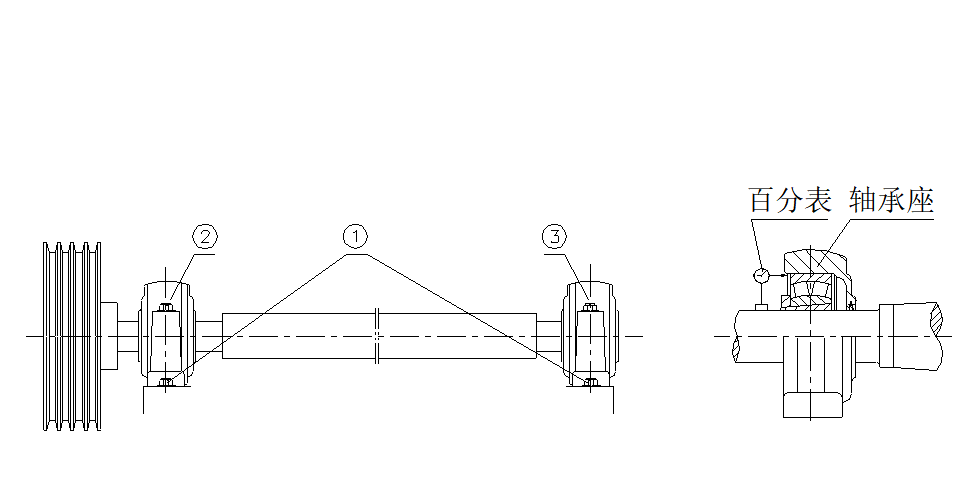

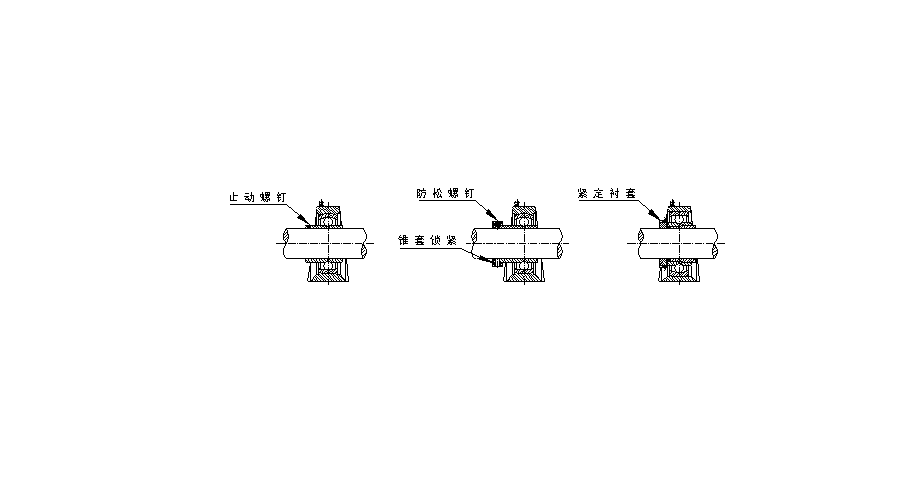

2.Ukufakwa kwebhokisi lokuthwala

Kufanele uqaphele amandla okuqondisa kwe-axile awanawo umthelela kuma-bearings lapho uqinisa wonke ama-bolts.

Ukusetshenziswa kwendlu yokuzala

Qinisa amabhawodi lapho endlini ethwele ngokusho umdwebo 8. Ngemva qinisa amabhawodi aphansi, ngoba indiza midsplit indlu bearing, okokuqala qinisa khulula amabhawodi ohlangothini kancane, ngokuvamile, sithatha motor ohlangothini njengoba ohlangothini olungenazibopho, ngoba fan ashisayo kanye fan eliqhutshwa uhlobo E futhi ukhethe ohlangothini hasn't motor, bese uqinisa amabhawudo ohlangothini amabhande.

Kumele ucabange ngomkhathi wokushisa okuphezulu kwefeni.

Izindlela zokulungisa i-shaft nama-bearings

Umdwebo 8 Umdwebo 9

Beka phansi ikhava engemuva, layisha iwashi le-centesimal, thatha indawo yokunquma ngama-periphery of bearings (uma kungenakwenzeka, thatha uhlangothi lwendlu yokuzala). Vula i-shaft kancane, bese ufunda futhi umaka inani elikhulu nelincane kakhulu. Bese sithola inani le-wiggle T, leli nani lilingana nenani elikhuphukayo naphansi khipha inani lesokudla nesobunxele. Uma ibanga ukusuka endaweni yokuhlola ukuya kuma-eksisi lingu-R, u-T ohlukaniswe u-R ulingana nenani legradient.

Inani elivumelekile legradient lamabhere amarola aziqondanisayo anemigqa emibili namabhola ahlukile kuye ngosayizi nesimo sokulayisha. Ngaphansi kwesimo sokulayisha esijwayelekile kuzoba phakathi kuka-1.5o~ 2.5o. Ukuthi leli nani lokusetha lingafinyelelwa yini, kuya ngedizayini yokucushwa kwamaphethelo namamodeli okuvala.

Ukusebenzisa i-bearing

Nakuba ama-bearings ana-2°ububanzi obulungisekayo ngokusebenza kwayo okuzenzakalelayo, kungcono unake ukufakwa ngoba ubakaki wale yunithi umane kakhulu:

Iyunithi yokuthwala enamabhawodi ayeka ukunyakaza

Yenza i-bore kanye ne-orientation ngemuva kokulungisa ibanga phakathi kwama-bearings. Izimbobo zokuma kokuma kufanele zifane nesicelo. Kufanele unake ukuqala nokushintsha amabhawodi usuku nosuku. Uma kungenjalo kuletha ezemidlalo eziphambene phakathi kwekhava yangaphakathi namabheringi. Bheka umdwebo 10.

Ngokomthetho we-wedge, inhloso yokulungisa ama-bearings ku-shaft yinhle. Faka iringi ye-eccentricity engxenyeni enwetshiwe lapho ene-eccentricity, bese uyiqinisa. Ngesikhathi esifanayo, qaphela ibhawudi. Bheka umdwebo 11.

Ukudweba 10 Ukudweba 11a Ukudweba 11b

Isebenzisa i-tight position bushing ukuze ifinyelele ukulingana phakathi kwe-bearing, isihlahla kanye ne-ekseli. Ngesikhathi sokufakwa, sicela unake ukuthi lapho ukuthwala kucindezelwa esihlahleni esiyindilinga futhi amantongomane angama-screw ayindilinga ayaqiniswa, ukunyakaza kwe-radial kuzovela futhi indawo engaphakathi ye-radial yokuzala izoncishiswa (umdwebo 11b). Sincoma ukuthi uvumele uchwepheshe onolwazi asebenzise i-hook wrench ukuze aqinise lawa mantongomane.

3.Notarize isiqondiso motor

Qaphela ukuthi akukho okungavamile lapho ufaka injini.

Qinisekisa ukuthi isiqondiso semoto silungile ngaphambi kokulenga ku-V-belt noma ufake i-shaft joint.

≤0.15~0.20mm Iphutha leRadial b≤0.15~0.20mm

I-4.V-ibhande kanye ne-pulley

Hlola ibhande le-V kanye ne-pulley ngaphambi kokuqala kwabalandeli, buyekeza isikhungo phakathi kwama-pulleys amabili futhi ulungise uhlobo lwe-V-belt.

Bheka isahluko sesithupha mayelana nokugcinwa nokuhlolwa kwesondo lebhande ne-V-belt.

5.Ukulungiswa okuhlangene kwe-Shaft

Lapho ufaka ifeni eshayelwa ijoyinti ye-shaft, ukuthuthukiswa okuhlangene kwe-shaft. Okokuqala khipha ama-bolts, beka phansi iphinikhodi, vula amathreyi e-flange, uhlole ukuvuthwa kwemoya ngesikhathi esifanayo. Ngokujwayelekile, ububanzi be-windage bubonisiwe kumdwebo 12.

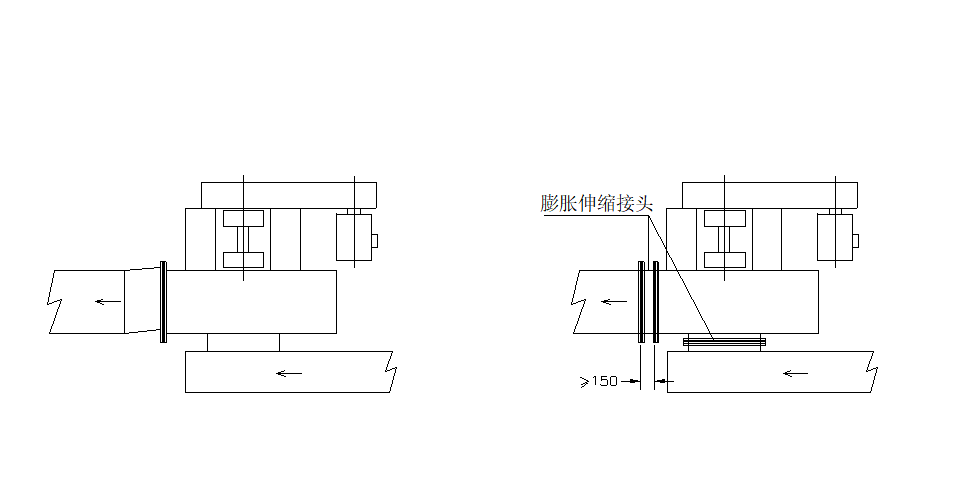

6.Ukuhlanganiswa kwepayipi

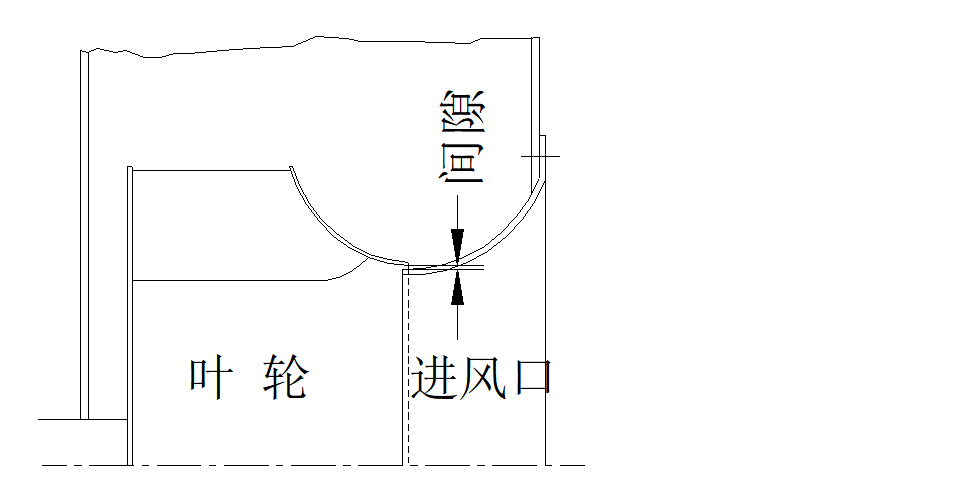

I-fan ihlanganiswe nepayipi eguquguqukayo, qinisa amabhawodi ngokulinganayo, thola isikhungo esingaguquki, ngaphandle kwalokho, i-anamorphic casing izovusa ukungezwani phakathi kokungena kanye ne-impeller.

Hlola ifeni ngaphakathi ngaphambi kokujoyina, kufanele uhlanze i-eyewinker.

Setha inetha yokuphepha enamandla okwanele endaweni yokungena lapho ifeni ingeke ihlanganiswe nepayipi.

Ekupheleni kokufakwa, hlola imvume phakathi kwe-impeller ne-inlet, qinisekisa ukuthi imvume i-symmetrical futhi ayiguquki. Bheka umdwebo 15

7.Ukufakwa kwe-hot-air blower

Ukuze ugweme umphumela wokunwebeka ngokushisa kufeni.

1.Ijoyini lokungena nokuphumayo

Kumele kusetshenziswe i-tie-in ene-inflatable, ingcindezi yokushisa ayikhokhiswa ngefeni. Epayipini lesakhiwo sepuleti lezikhali, izinga lokushisa lishintsha ngo-100℃ njalo ngo-1000mm, ivolumu yokuhlanekezela icishe ibe ngu-1.3mm. Bheka umdwebo 13.

Kahle Kahle

Umdwebo 13

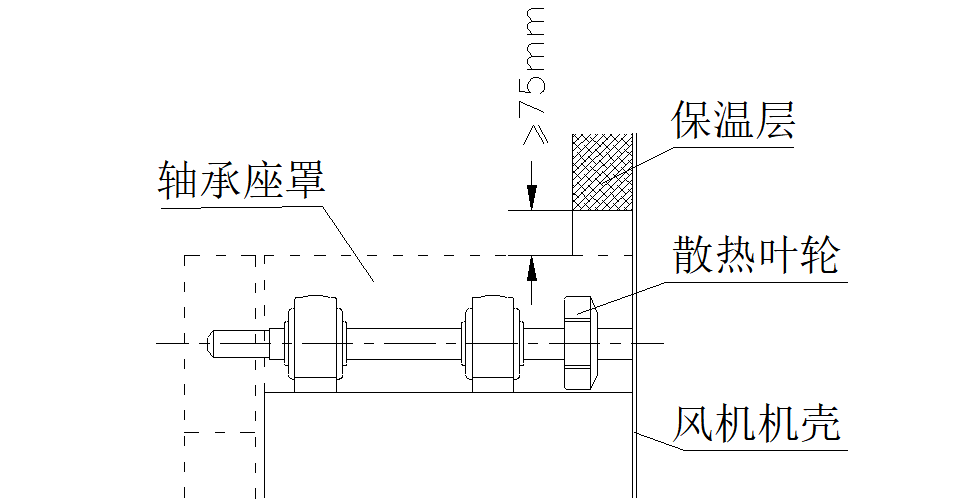

2.Ukuphola kokuzala

Ukuze unciphise umphumela wezinga lokushisa eliphakathi nendawo, faka i-fan yokukhipha umoya (yezinga lokushisa legesi elingaphansi kuka-250 ℃). Futhi musa ukubiyela ngaphandle kwefeni. Bheka umdwebo 14.

Umdwebo 14

Umdwebo 15

5.Ukuthunywa

Inqubo kanje:

Hlola

Qinisa amabhawodi namantongomane ngamunye ngokulinganayo, noma kuphakame umsindo, ukukhululwa, ukuchitheka komoya kanye nokuhuzuka kwamabheringi kanye ne-shaft.

Faka umusi

Ama-bearings afake okokugcoba okufanelekile, uma ufuna ukuphinda afakwe, kufanele aqinisekise ikhwalithi yokugcoba.

Gqoka umusi ngokulandela isiqondiso.

Sicela ubheke isahluko sesithupha ukuze ugcwalise amafutha okugcoba.

Jigger

Sicela unake ukulandela lapho uvula i-impeller:

lalela umsindo

Uma umsindo ulalela ngokungajwayelekile, sicela uqaphele.

okunye

Ukunwetshwa kwebhande le-V.

Umuzwa usinda kakhulu we-jigger.

Isistimu yokondla umoya

Zonke izingxenye zihlangabezana nesidingo.

I-eyewinker eduze nendawo yokuphuma noma kufeni.

Uma isebenza, uma kunokungavikeleki endaweni ephuma kuyo.

Izinto zikagesi

Qinisekisa ukuthi awukho umjikelezo ovulekile ohlelweni.

Hamba phezu kokuxhumana ebhokisini lokuhlangana.

Qalisa

Ukuqala ngemuva kokuqinisekisa i-oda lesistimu yabalandeli, isistimu kagesi neminye imishini. Vula iswishi, vala ngemva kwemizuzwana engu-3~6, qinisekisa ukuthi ukujika, ukukhishwa nomsindo kulungile.

Kulesi senzo esisheshayo, hlola futhi ulungise ngokuya ngokulandisa phambili uma kukhona okungavamile, bese uqalisa futhi.

Amandla kagesi anezikhathi ezingu-5~7 zokulinganisa amandla kagesi we-fan ad motor lapho uqala, bese wehlisa kancane kancane. Uma amandla kagesi ehla kancane kakhulu, kufanele uhlole isistimu kagesi.

Kuqashwe ukusebenza

Uma kunesidingo, vula noma uvale umnyango wokulungisa kancane kancane ngemva kokuthola inani ku-amperometer.

Maka amandla kagesi kanye nengcindezi

Hlola ukukhishwa, izinga lokushisa kanye nomsindo wama-bearings.

Phakathi neviki kusukela ekuqaleni kwabalandeli, sicela unake okulandelayo:

Ukungqubuzana kwama-rotors

Phakathi kwe-impeller ne-inlet

Phakathi kwe-impeller ne-casing

Phakathi kwe-shaft ne-casing

Phakathi kwe-V-belt nesembozo sebhande

Ibhande le-V-belt

Hlola ibhalansi ye-V-belt

Ibhande le-V

Ukuhushulwa kwebhande le-V

I-Swing of shaft joint

Ukuchezuka kwevalvu elawula i-foliose.

Okunye

Ukuhogela ama-eyewinkers

Ukukhululwa kwe-fan self

Ngemva kokuhlolwa, vala isistimu ukuze ulungise ibhande le-V.

Hlola ama-bearings ne-lubricator yawo.

Okwefeni yezinga lokushisa eliphezulu ngaphandle kwe-jigger, vala isistimu lapho izinga lokushisa langaphakathi lehla libe ngu-100℃.

Ukusebenza akukwazi ukushintshwa ngokukhuphula isivinini sokuzungezisa. Kungenjalo kuletha ingozi.

Ukunakekela nokuphatha

Ukuhlola kuhlukaniswe kwaba isheke lezikhathi ezithile kanye nesheke lansuku zonke. Kungcono unake ingxenye yokudlulisela ekuhloleni kwansuku zonke.

Uma ifeni igijima kahle phakathi nokugijima, hlola ngokwezimo ngokweshidi 2 ngebanga lamaviki angu-2–3.

| hlola ingxenye | into | okuqukethwe |

| imitha | i-amperometer I-voltmeter i-tachometer | Ukuthi imitha inokungajwayelekile yini?ukuthi umbono unokuthile okungavamile? |

| ibhokisi

| qhaqhazela | Ukuthi amabhawudi ayavumelana nezimo yini?Ingabe ukuhlangana okungaphezulu nohlaka kuye kwagoqwa? |

| i-blowby | Kungakhathaliseki ukuthi uphawu lwabhujiswa? | |

| ibhokisi | qhaqhazela | Ukuthi amabhawudi ayavumelana nezimo yini?Ingabe ukuhlangana okungaphezulu nohlaka kuye kwagoqwa? |

| i-blowby | Kungakhathaliseki ukuthi uphawu lwabhujiswa? | |

| impeli | Gcoba nge-casing | Ukuthi imvume yokungena iwukulingana yini?Ingabe imvume ene-casing iyalingana?(i-axial fan) Ukuthi injini igcina ifakwe i-casing? |

| impeli | qhaqhazela | Ukuthi uthuli lunqwabelene kabi yini?ukungalingani Ukuthi amabhawudi ehabhu ayavumelana nezimo? |

| ukuhlanekezela impeller | I-Cauterization abrasion kanye nokuhlanekezela kuyasabeka | |

| ukuhlanekezela impeller | Kungakhathaliseki ukuthi ingxenye yama-bearings afakiwe kanye nesembozo esithwalayo yacekelwa phansi? | |

| ukuzala indlu yokuzala | qhaqhazela, ukushisa, umsindo

| Ukuthi amabhawodi nama-gaskets ayashintshashintsha yini? Ukuthi amafutha avuzayo? Uma uphawu likhulu ngokweqile? Ukuthi okokugcoba kudlulele futhi kungcolile? Hlola umsindo nge-stethoscope. Ukuthi izinga lokushisa liphakeme ukuthinta ngesandla kanye ne-thermometer? |

| isisekelo | qhaqhazela | Ukuthi amabhawudi aphansi ayavumelana nezimo yini?Ingabe isisekelo sihle? |

| ipuli Ibhande le-V ukuhlanganyela kwe-shaft okunye | i-flap, ukushisa | Ukuthi amabhande ayashibilika futhi ayashibilika yini?Ingabe ama-pulleys ayalingana? Ukuthi okhiye bayavumelana nezimo? Ukuthi amasondo ebhande ane-attrite? Ibhande alanele. Ubude bawo wonke amabhande abufani. Ukuthi ukushwiba kwejoyinti le-shaft kudlula ukubekezelelana? Ukuthi amabhawudi angaguquki ayavumelana nezimo?

|

Ishidi 3 lizokukhombisa ukuthi uthole amaphutha kalula.

Ishidi 3 Ukudubula Inkinga

| iphutha | isizathu | Isilinganiso |

| Ivolumu incane kakhulu | umfutho omile oklanywe waba mncane kakhulu amapayipi ukuvuza komoya kanye ukumelana kukhulu kakhulu isicabha sokulungisa sivuleke sincane kakhulu ukuphenduka kuyiphutha ijubane liyancipha ngoba ukushibilika kwamabhande | transvaluation of the design lungisa ngemva kokuhlolwa lungisa beka ngesikhathi lungisa uhlobo lwamabhande |

| ukulayisha ngaphezulu kwemoto | amabhande aqine kakhulu iphutha lemoto ekhethiwe umfutho omile odizayinelwe waba mkhulu kakhulu umnyango olungisayo ulungiswe kabi amaphutha motor | lungisa uhlobo lwamabhande shintsha yehlisa isivinini sokuphenduka lungisa futhi lungisa noma ushintshe |

| umsindo ongavamile | udoti ohlanganisiwe: ukuqhekeka noma isibazi ukuhuzuka kwe-shaft ukungqubuzana kwe-impeller I-locknut yama-bearings iyashintshashintsha shaft shaft uhlobo lwefeni ye-pip system olubi lungamanga ukugeleza komoya ngokuhefuzela amalunga amapayipi mabi | shintsha shintsha shintsha qinisa amabhawodi qinisa amabhawodi futhi thola isizathu bese ulungisa yakha kabusha isistimu noma khetha ifeni futhi lungisa futhi |

| umsindo ongavamile | ephambanisa ama-ewinkers umthamo womoya mkhulu kakhulu | susa yakha kabusha isistimu yepayipi |

| izinga lokushisa hoik | ukuthwala ukushisa namaphutha ububi bokufakwa impeller ububi of balance ukugcoba ngokweqile ukuntula okokugcoba kanye nohlobo lokuthambisa lungamanga i-motor over loading, ububi bokuzihlukanisa ukungqubuzana ezingxenyeni ezivaliwe | lungisa i-crack noma shintsha i-bearing lungisa isikhungo futhi uqinise amabhawodi angashintshi buyekeza ibhalansi ye-impeller sula okuchithekile supply lipin, exchange lubrication entsha lungisa umthwalo, lungisa ukuhlukaniswa lungisa noma ufake futhi |

| ukukhululwa | ukuqina kwesisekelo akwanele ububi bomklamo amabhawodi aphansi ayavumelana nezimo ukungalingani kwe-impeller ukulimala kwama-bearings ukuhuzuka kwe-shaft skid of amabhande umphumela ovela ekukhululweni kwangaphandle ukushwibeka kwejoyinti le-shaft kudlula ukubekezelelana uhlobo lwabalandeli lungamanga | qinisa, thuthukisa

qinisa Hlanza i-impeller, ubuyekeze ibhalansi ukushintshana ukushintshana lungisa ukunwebeka sebenzisa i-gasket eqinile lungisa futhi khetha futhi |

Phawula: le misindo kufanele ilinganiswe ngochwepheshe abanolwazi oluningi.

Ngokuvamile, amaphutha e-fan anomsindo, ukukhulula kanye nezinga lokushisa elishisayo, ngakho-ke, ukuhlola kwansuku zonke kubalulekile.

Ukukhululwa

Ngomugqa omaphakathi wenjini nendlu ethwele, nquma futhi umake inani lokukhishwa kusiqondisindlela esingu-X, Y, Z ngokuya nge-JB/T8689-1998 evamile.

Uma umphumela uhlukile kokujwayelekile, buyekeza ukufaneleka.

Asithembi ukuthi abalandeli bazosebenza ngaphansi kwezinga, noma ngabe ifeni engasetshenzisiwe ibonile.

Umsindo

Uma ifeni inomsindo oyingqayizivele, qinisekisa izimbangela ngesikhathi kanjena: ukushibilika kwamabhande, amalunga ayaguquguquka, eyewinker, ama-bearings, motor. Ikakhulukazi hlola ama-bearings.

Sicela unake izinga lokushisa lama-bearings wendlu kanye ne-casing. Uma uphikelela kumasekhondi angu-3–4 uma uthinta indawo engaphezulu, lapha futhi manje izinga lokushisa lingu-60℃.

Amazinga okushisa e-Motor ahlukile ngenxa yebanga lokuhlukaniswa. Izinga lokushisa elilinganiselwe lokusonta: Ibanga B lingu-80℃, ibanga F lingu-100℃.

Amasondo amabhande ohlangothini oluphezulu lwezinga lokushisa azovusa ukushelela kwebhande lapho ifeni ima. Kufanele ulungise uhlobo.

Ukugcinwa nokuhlolwa kokuzala

Sicela ubhekisele ebhukwini lesitayela mayelana nokusebenza kwe-bearing.

Sicela ubhekisele kulokhu kanye nezicaciso zefektri mayelana nokufaka nokuqaqa.

Impilo yemvelo yokuzala

Ngokuhambisana nemithwalo ethwalayo, izindinganiso zasekhaya nezangaphandle, impilo yemvelo yama-bearings amahora angama-20000 ~ 30000 ngokuvamile eduze kwecala elikhethekile.

Uphawu lokuhweba, isikhawu sokwengeza, inani le-lube

Uma isimo esivamile sifana ne-standard heat degree, bheka ishidi elithi 4.Cabanga ngophawu lokuhweba ukuze uthole isivinini esikhulu sokuzungezisa kanye nezinga lokushisa eliphezulu ikakhulukazi.

| lube

okuqukethwe | ukuzala kwasekhaya | ukuthwala okuvela kwamanye amazwe | ||||

| ukugcoba | ukugcoba | ukugcoba | ukugcoba | |||

| isici | evamile | evamile | izinga lokushisa eliphezulu | evamile | evamile | izinga lokushisa eliphezulu |

| uphawu olujwayelekile | I-GB443-89 | I-GB7324-94 | igobolondo gadus s2 v100 2 | I-GB443-89 | igobolondo gadus s2 v100 2 | igobolondo |

| ikhodi | I-L-AN46 | 2# | R3 | I-L-AN46 | R2 | R3 |

| igama | amafutha enjini | Li fat | Li fat | amafutha enjini | Li fat | Li fat |

isikhawu sokwengeza

Okufanayo, yengeza ngokweshidi 5. Uma esimweni esisebenzisekayo noma isistimu isebenza ngokuqhubekayo emahoreni angama-24 noma ihamba othulini namanzi, isikhawu sokwengeza siyingxenye yeshidi lesi-5, futhi sebenzisa isihlangu kuma-bhering.

Gcoba i-lube kancane uma ifeni igijima ngesivinini esiphansi noma igeze ngesandla.

Amanani e-append luba ingxenye eyodwa kwezintathu kuya kuhhafu ye-cubage ethwele noma ethwele indlu. I-Nimiety iyingozi.

ishidi 5 isikhawu selube sokuzala sokuzala kanye nendlu yokuzala

| izinga lokushisa elisebenzayo lokuthwala (℃) | r/min zungezisa isivinini | ||

| ≤1500 ngaphansi kuka-1500 | >1500 ~ 3000 ngaphansi kuka-3000 | >3000 ngaphezulu kuka-3000 | |

| ≤60 | 4 izinyanga | 3 izinyanga | 2 izinyanga |

| >60≤70 | 2 izinyanga | 1.5 izinyanga | Inyanga engu-1 |

| >70 | ukukhuphuka kwezinga lokushisa ngo-10 ℃, hlukanisa isikhathi sokungeza ngohhafu (imvume ikhuphuka ≤40℃) | ||

vula ibhokisi elithwalayo ukushintshanisa ilube

Kunoma ikuphi, vula ikhava yebhokisi elinophawu ukuze uhlole kanye ngonyaka okungenani. (Ngaphandle kwama-bearings

Ingabe zikhona izibazi kanye nemifantu kumabheringi?

Ingabe umphetho wokuthwala uxhumene kahle nebhokisi lokuzala? Ingabe ingxenye yamahhala ihamba ngokujwayelekile?

Isengezo se-lube sebhokisi elithwele ngokwefasitela likalayini we-lever yamafutha (bheka uphawu lwe-NOTE

Enkabeni ye-shaft nendlu yokuzala, wonke amabhawodi nama-gaskets aqinile.

Gcoba ilube entsha ngemva kokugeza ama-bearings.

izinga lokushisa eligijimayo

Izinga lokushisa elingaba ngu-40℃~70℃ endaweni ethwele lingokwemvelo, uma kungenjalo, lapho izinga lokushisa lilikhulu kuno-70℃, kufanele lihlole ngesikhathi.

Ukugcinwa nokuhlolwa kwejoyinti le-shaft

Lawula i-wing windage ngokucela ngokuqinile

Ukushintsha iphinikhodi egugile ngesikhathi.

Ukugcinwa nokuhlolwa kwe-pulley l ne-V-belt

Ibhande le-V

Amaphutha kumele abe kwisibopho esivumelekile uma amasondo anezikhala ezithile.

Iphutha elikhulu lobude lithinta ukukhathala, ukukhululeka kanye nempilo yemvelo.

Khulula amabhawodi lapho ngaphansi kwesisekelo se-motor, faka amabhande ngemuva kokuthola ibanga elincane lesikhungo, uma uklomelisa amabhande ku-slots, amabhande azoqhuma.

Ukunciphisa impilo yemvelo lapho amabhande egcotshwe ngamafutha noma uthuli, ikakhulukazi amafutha.

Izimbazo ezimbili kufanele zihambisane, ngaphandle kwalokho, ukugqokwa kuzokwehla.

Sicela ulungise ukungalingani ngaphansi kuka-1/3°. (Bheka umdwebo 17)

Isikhathi sokuthumela: Sep-27-2023